Specifications

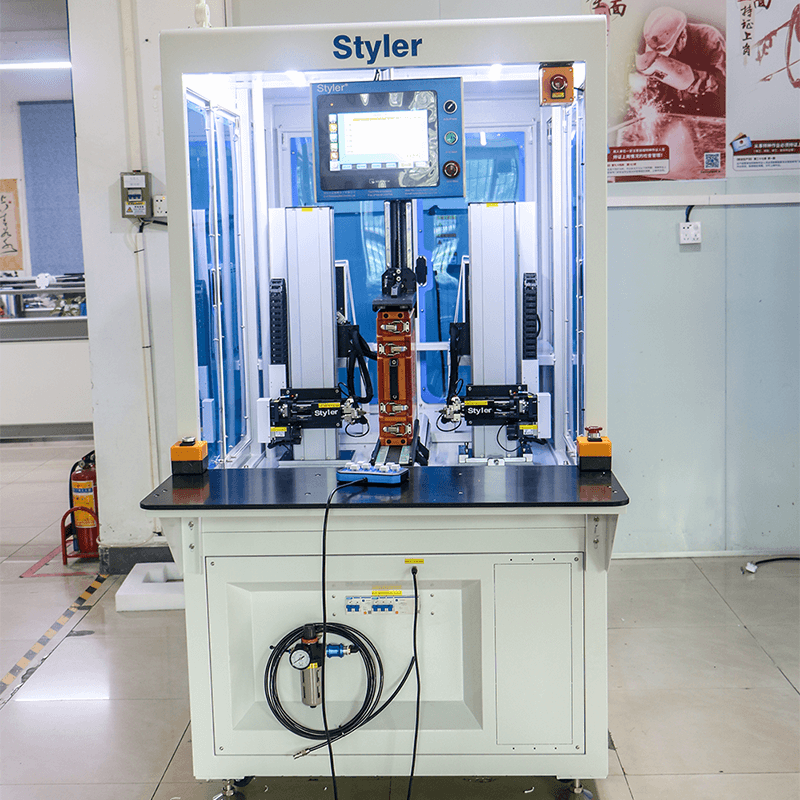

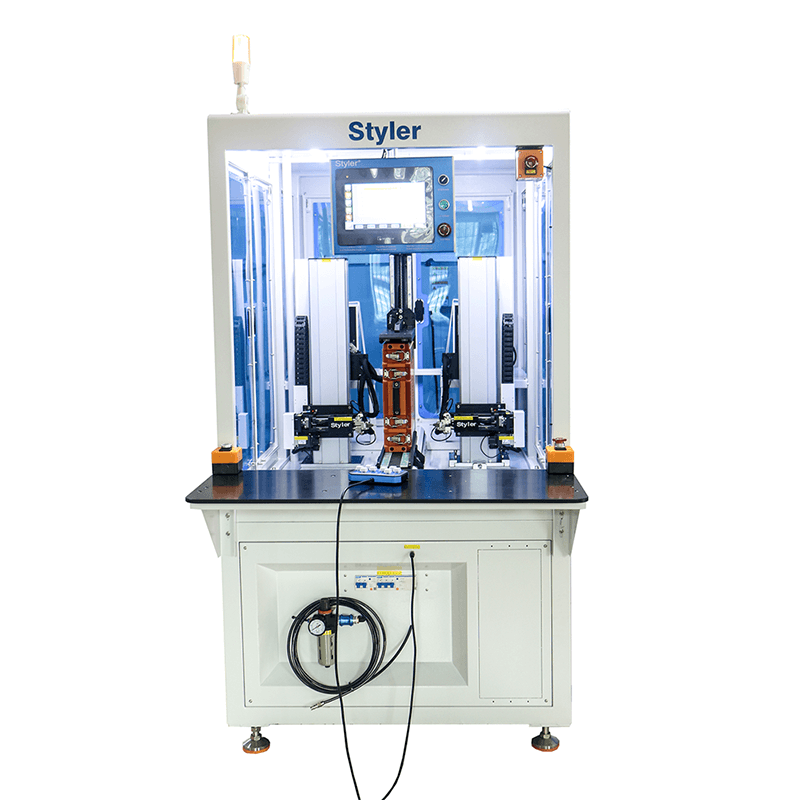

A fully automatic dual-head spot welding machine designed to provide high-precision and simultaneous welding for battery packs, increasing production efficiency.

Machine Scope

Equipped with advanced positioning systems, automatic needle compensation, and real-time monitoring, it delivers consistent quality and reliable performance in high-volume production environments.

Duo-Headed Automatic Welding Machine

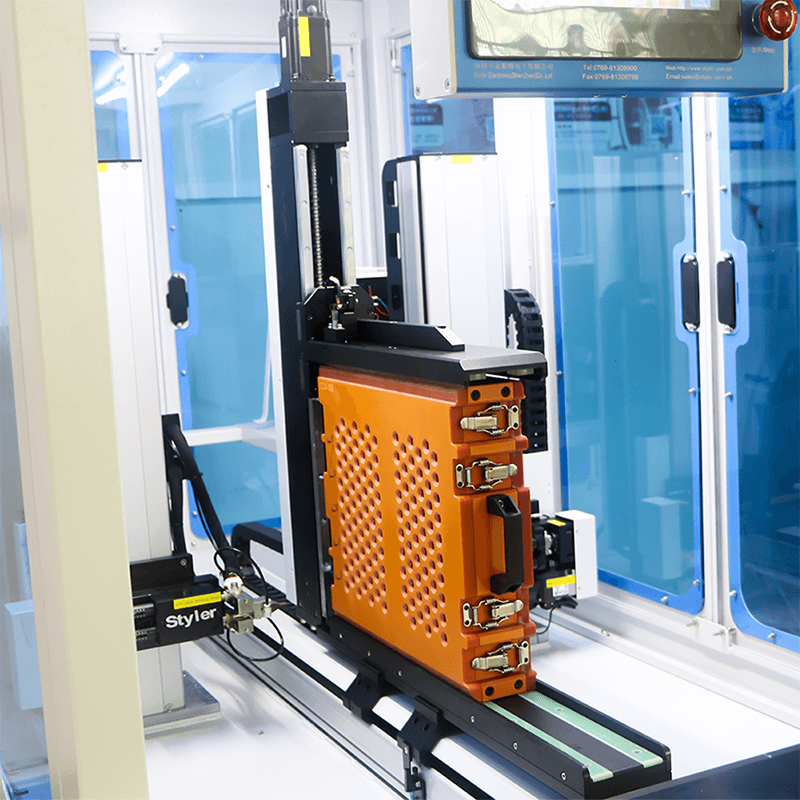

This fully automatic spot welding machine is engineered for high-precision welding in a fixed direction. Its dual-side simultaneous operation increases production efficiency without sacrificing performance. An electromagnet positioning unit, cylinder compression system, and service control system ensure accurate placement of battery packs. Maximum supported pack size is 600 × 400 mm, with a height of 60–70 mm.

Product Features

-

High-frequency inverter-based digital control

-

High-precision welding for battery connectors and small metal components

-

Intuitive parameter adjustment via microcomputer control

-

User-friendly LCD parameter display

-

Low spark generation and discoloration-free weld surfaces

-

Short welding duration with minimal thermal effect

-

Precise heat management protecting internal cell properties

-

Homogeneous heat distribution for long-lasting bond surfaces

Specifications

-

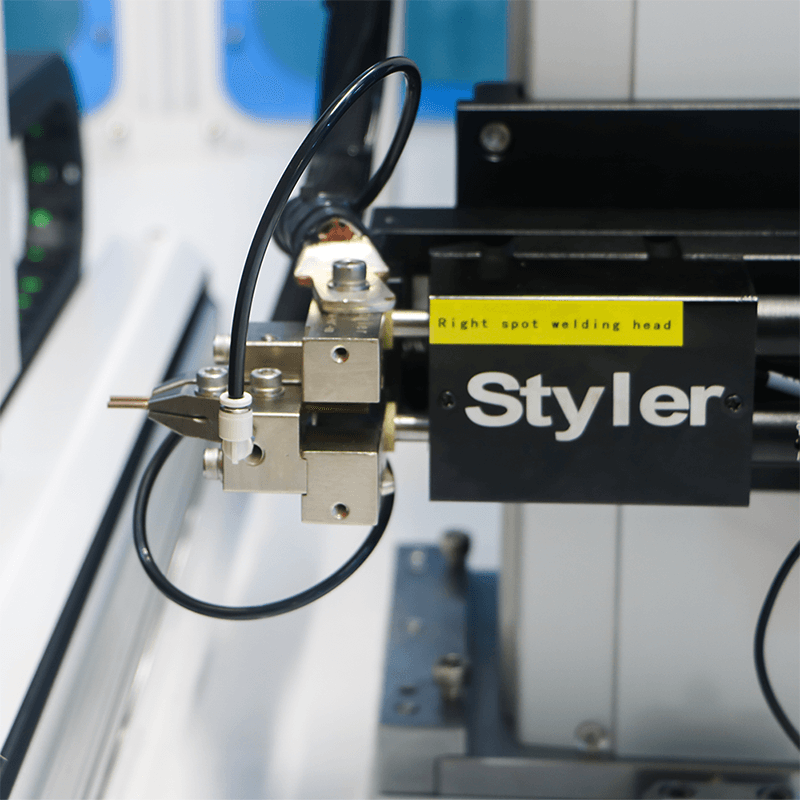

Dual-head simultaneous welding mechanism

-

Automatic Needle Compensation (position detection & needle grinding alarm)

-

Step-welding function

-

Electromagnetic battery positioning support

-

Automatic verification with battery pack detector

-

Stable pressure control via cylinder compression device

-

Integrated service control system

-

Max. package size: 600 × 400 mm

-

Max. height: 60–70 mm

-

Real-time welding data transmission via RS485

-

90° rotatable chuck for rapid directional switching

-

Forward/backward Z-axis travel control

-

Replaceable display interface

-

Virtual break-point welding function

-

Industrial design optimized for mass production

-

Motor + lead-screw driven pressing spindle

Application Areas

-

Lithium battery pack production

-

Electric vehicle battery modules

-

Energy storage system modules

-

E-mobility devices

-

Power cell interconnect components

-

Small metal hardware

-

Electrical & electronic assembly

-

Model and device fabrication

Optional Accessories

-

Safety Guard (IR Sensor): Detects foreign objects or hand contact, triggers automatic stop/alarm.

-

Access Control: Automatically shuts down machine when the enclosure door is opened.

-

Real-Time Weld Spot Monitoring: Supports RS485 data transmission.

-

Fixture: Customizable clamping assembly for stabilizing battery packs.

-

Scanning Gun (QR/Barcode): Automatically selects welding programs based on code scanning.

Product Details

#automaticweldingmachine #dualheadwelding #spotweldingmachine #laserwelding #automaticspotwelding