Specifications

Spot Welding of Batteries is the Most Efficient Method of Joining Without Heating and Damaging the Internal Structure.

Specifications

The iCANweld Machine Stands Out with the Ability to Learn Spot Locations from Mold Drawings and Offers Easy Use.

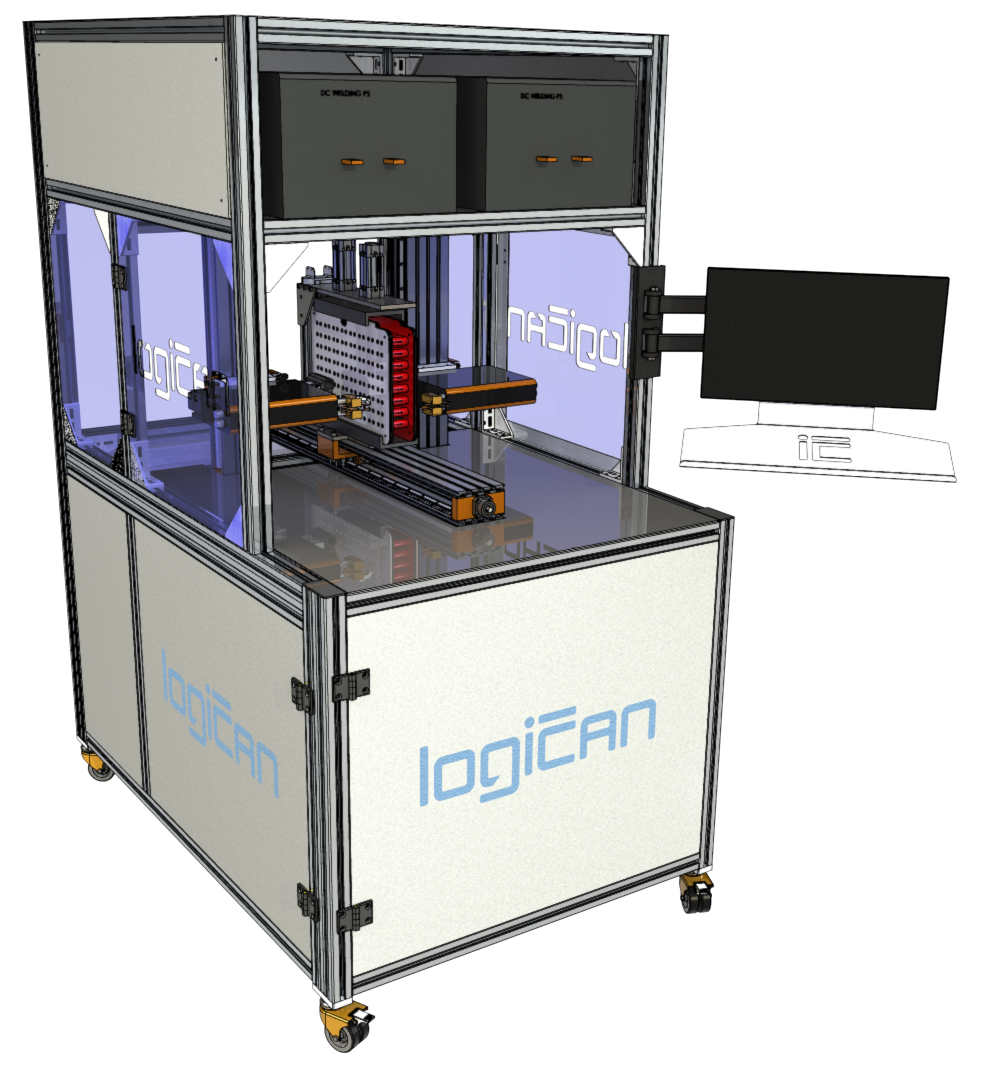

Dual-Sided Automatic Spot Welding Machine

Specifications

- Real-time spot energy control

- Spot tip maintenance time notification

- Ability to pause during operation for maintenance

- Automatic return to position after maintenance

- Ability to spot weld on both sides simultaneously

- Axes with 10µm precision

- Computer-controlled system with single interface

- Emergency stop and alarm system

- Compatible with all cylindrical batteries (18650, 21700, 26650, 32650, 32700)

- Nickel and nickel-plated stainless steel up to 0.2mm thickness

- Not usable for spot welding copper conductors

- 30 spot welds per minute

- Spot energy source (capacitive discharge)

- Sunstone CD400DP 2 units

- Moving Axes

- 3 servo motors with 20bit encoder

- Total Power: 1.2kW

- Other Systems

- Total Power: 1kW max

- Windows 11 based computer

- Ethercad communication feature

- Turkish interface

- Ability to analyze the battery mold from .dxf drawing and create spot locations

- Ability to store over 5000 different mold files

Battery molds are not suitable for manually prepared conductors. Conductors should be either purchased from ready conductor manufacturers or designed and supplied pre-cut.

- Magnet-integrated plastic mold

- Initial mold design data shared

- Different mold design and production is easy and fast

Machine Dimensions: Width: 1000mm Length: 1500mm Height: 2000mm Total Weight: 350kg Max. Battery Block Dimensions: Length: 210mm Width: 300mm (Special design available for larger battery molds)

Max. spot distance in the vertical axis: 210mm, max. spot distance in the horizontal axis: 300mm. Within this range, all desired spot hole patterns can be accessed, and the computer interface automatically defines holes from the mold drawing and assigns spots to the selected holes. The mold holder can accommodate up to 70mm long batteries with their molds.

#spot welder #battery spot welding machine #automated li-ion cylindrical cell welder #spot welding machine